Thermoindicator of melting of TIN type

Characteristics

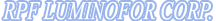

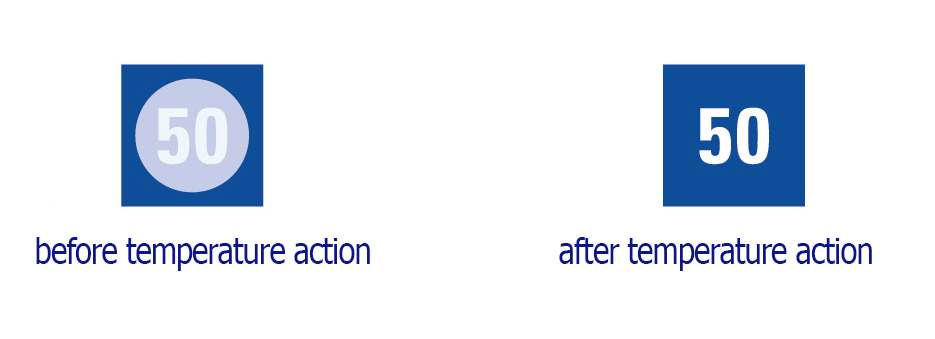

Compact thermoindicator patches represent the substrate on the self glueing base with the applied thermoindicator coating. The substrate material is either paper, foil or polymeric film. To protect the thermoindicator coating against outside influence, the article surface is covered with a protective film. When the specified temperature is achieved, the indicator colour is irreversibly changes from white into black.

TINs are manufactured by the Technical Specification (ТУ) 20.59.52-067-48591565-2020. Thermoindicator patches are manufactured of different shape with the range of measurement from 40 °C to 300 °C and the number of thermosensitive marks on one patch is from 1 to 10. Thermoindicator patches based on paper and polymeric film are used in the temperature range of 40-100 °C, based on foil – 40-300 °C.

The values of controlled temperatures may be as the following:

40, 47, 50, 54, 60, 65, 72, 75, 77, 82, 85, 90, 95, 100, 105, 108, 114, 118, 122, 127, 135, 142, 146, 152, 160, 170, 180, 190, 200, 215, 222, 232, 238, 255, 270, 280, 300 °С.

The size and shape of patches and the number of marks on the same patch and the material of the substrate is presented according to the customer request.

Since 2021, TINs are also available in a new design: size 7*7 mm, 15*15 mm, 30*15 mm, 160*20 mm.

size 7*7 mm size 15*15 mm

size 30*15 mm

size 160*20 mm

Application

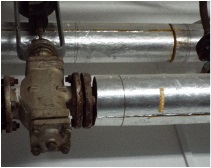

For productional and research practice for thermal regime control of:

-

electronic circuits and details;

-

in sterilization of food products and medical equipment;

-

on rotating parts;

- on current carrying parts in power engineering, radioelectronics and etc.

Advantages

The method of temperature measuring by means of thermoindicator patches is characterized by simplicity, effectivity, small labourousness and the possibility of operative obtaining full enough information of thermal conditions of constructions, sets and units in the wide temperature range of 40 – 300 °С.

They allow not only to control the maximum temperature of the object (with using one-positional TIN) and also to determine temperature of the studied surface as arithmetical mean between the last thermoindicator mark which changed its colour and the first mark which didn’t change its color (when using several one-positional patches for different temperatures or one multipositional thermoindicator patch).

The patches can be used such as confirmation of achieving the specified maximum temperature as the measurement results are irreversible.

Thermoindicator patches allow to reduce the expenses for the equipment repairing. They reduce the number of guaranteed cases caused by overheating and they increase the labour safety.

Thermosensitive coatings forming the patch composition were developed and are manufactured by the technical Specification (ТУ) 2638-002-48591565-2000 «Thermoindicators of melting, highsensitive». The accuracy of readings is ±1 % at heating rate up to 2 °C/min.

Operation conditions

Thermoidicator patches on the self-glueing base are characterized by good adhesion to various metals, hermetics, ceramics and other constructional materials.

Thermoindicator patches made on the substrate of self-glueing foil can be used in the conditions of aggressive medium (for example, burning products of oils, fuels), at atmospheric conditions (rain, snow, fog including the sea ones).

Thermoindicator patches made on the substrates of foil or polymeric film can work both at the atmospheric pressure and in vacuum.