Thermoindicator of melting of TIP type

Product form

Minimal order is 100 ml.

The sets of 4, 6, 8 names of thermoindicators are delivered in flasks with brush and of volume of 25 ml and 50 ml for each individual request.

Characteristics

Thermoindicators of melting (TIP) are high-dispersed suspensions of thermosensitive substances based on organic and inorganic chemical compounds and binders in organic solvents.

Most of TIPs are of white colour. When they response (melt) the investigated surface uncovers.

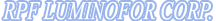

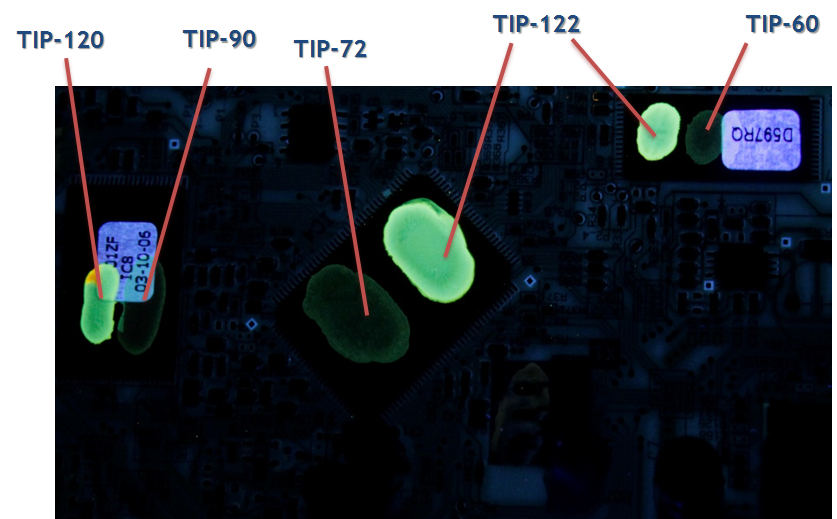

TIPs can additionally contain pigments-fillers (pigmented TIPs), dyers (coloured TIPs) or luminescent additives (fluorescent TIP). TIP with luminescent additives have a distinct contrast boundary of the colour transition which is clearly distinguished in not only daylight and electric light, but also in the dark under the influence of UV-radiation. The transition boundary can also be distinguished by the colour and intensity of the glow. TIP in the temperature range of 30-200 °C at UV-radiation (365 nm) before heating can have blue, green, yellow, orange or pink glow. The presence or absence of luminescence is an additional sign confirming the authenticity of the test results.

A protective film is delivered separately for the temperature range 50-255 °C. Increased humidity, solar radiation doesn’t influence the accuracy of TIPs readings (its measurement error is only ± 1 %).

The TIP’s temperature of melting does not depend on the temperature conditions.

Thermoindicators of melting can be applied on the investigated surface with a thinner layer (less than 0,04 mm). As a result, the working speed increases and coating mass decreases.

TIPs are manufactured by the Technical Specification (ТУ) 2638-002-48591565-2000 «Thermoindicators of melting, high-sensitive» of the following modifications:

|

TIP-30 TIP-33 TIP-35 TIP-38 TIP-40 TIP-47 TIP-50 TIP-54 TIP-60 TIP-65 |

TIP-72 TIP-75 TIP-77 TIP-82 TIP-85 TIP-90 TIP-95 TIP-100 TIP-103 TIP-105 |

TIP-108 TIP-114 TIP-122 TIP-127 TIP-135 TIP-142 TIP-146 TIP-152 TIP-160 TIP-170 |

TIP-180 TIP-190 TIP-200 TIP-215 TIP-222 TIP-232 TIP-238 TIP-255 TIP-270 TIP-280 |

TIP-300 TIP-322 TIP-330 TIP-360 TIP-375 TIP-390 TIP-400 TIP-480 TIP-500 TIP-530 TIP-560 |

TIP-580 TIP-600 TIP-620 TIP-640 TIP-670 TIP-700 TIP-720 TIP-750 TIP-800 TIP-830 |

TIP-860 TIP-880 TIP-905 TIP-950 TIP-960 TIP-980 TIP-1015 TIP-1050 TIP-1100 TIP-1150 TIP-1200 |

In TIP marking the digit index shows an approximate temperature of a coloured transition (the temperature of melting). The exact temperature is shown in the passport.

Examples of colour transition for coloured thermocoatings:

Thermoindicators of TIP type can be used in almost all cases of productional and researching practice for thermal regime control of:

- inside and outside surfaces of complex configuration;

-

current-carrying parts in energetic;

-

in electronics and radiotechnics;

-

in cosmic technics; ship building, in machine building, metallurgical, electrotechnic and other industries

-

rotating parts;

-

of artillery ammunition when storing and transportation;

-

for controlling the temperature furnace producing asbestos-cement pipes;

-

for controlling the temperature of brakes;

-

for controlling the temperature of locomotive transmission gear box;

-

for controlling the temperature of hot points in energy meters;

-

temperature control at food product sterilizing; in medical equipment; when drying seeds.

The same thermoindicator modification in the temperature range of 30-322 °C can be used both at atmospheric pressure and in vacuum. When operating in vacuum, use of a protective film is obligatory for a series of thermoindicators. The protective film is the transparent lacquer protecting the surface of the thermal coating from the effects of aggressive media and evaporation.

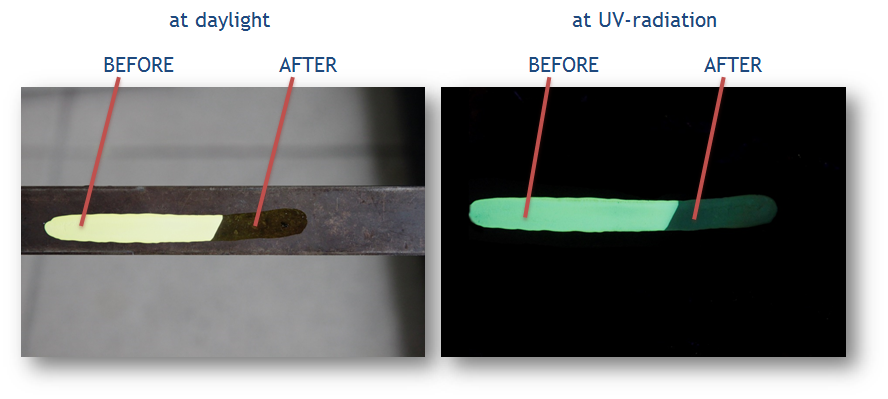

Thermoindicator materials are used for overheating control of MC or chip cards in the electronics:

View of thermoindicator coating at UV-radiation:

This property of TIPs is used in condition of poor visibility and also as additional security element from counterfeit products.

Advantages

The method of temperature measuring by means of TIPs is simple, effective, with small laboriousness and gives the possibility to get operatively the full enough information of the thermal conditions in constructions, sets and units in the wide temperature range.

TIPs allow simply and availably to determine the surface temperature distribution in the aircrafts and other objects. This analysis is not possible by using thermocouples. TIPs can be removed from the investigated surface mechanically or with a solvent, and the investigated object can be reused for further temperature testing. If you use thermocouples or thermocrystals re-use will not be possible because the surface of the investigated object is broken. The cost of thermoindicators of melting is much less than the cost of installing temperature sensors on the investigated surface.

TIPs not only allow to control the maximum temperature of an object but when provided the coating of a number of thermoindicators (as lines, dots) is applied to determine the temperature of the investigated surface as an arithmetical mean between the last thermoindicator mark which changed the colour and the first one remained unchanged.

When melting, the pigmented TIPs are also held out in the field of centrifugal forces under action of powerful gas flows.

TIPs allow to determine the temperature gradient on the whole controlled surface. The fixation of temperature fields determined by TIPs can be conducted by means of both coloured and black-and-white photography.

Operation conditions

Coloured and pigmented TIPs provide an increased contrast of colour transition and are recommended for controlling and measuring the temperature of the object heated surfaces made of any constructional materials including white ceramics, glass and quartz. You can use TIPs with the luminescent additives in the darkness at UV-excitation (365 nm) source.

Thermoindicator coating with a protective film endures different climate conditions: that is, increased humidity up to 98% at the temperature of 50 °C; water action; temperature cyclic variations from -60 °C to +25 °C. It is stable to the influence of aggressive media (for example, burning products of oils, fuels) and atmospheric conditions (rain, snow, fog as well as sea fog).